.................................. Return to Sumner's Home Page....

Return to N Scale RR Main Menu.............. Return to Trackwork Menu

=========================================

..............Previous Page..............................Next Page If There Is One

=========================================

a --- Using a Servo with 1” Foam Board --- Servo for Turnout Control ---

=========================================

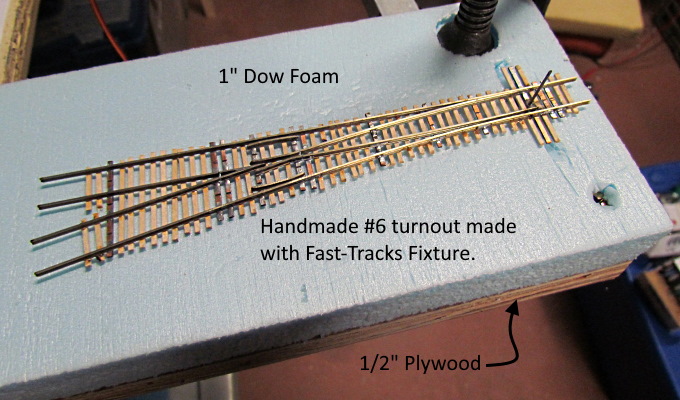

I was interested in knowing if I could control the turnout points with a servo that was mounted under 1/2” plywood and 1” of foam board. I set up a jig to try this out and just held the turnout in place with my hand as I threw the servo using the controller described on the page before this one.

I had success and feel this will work. In the three yard areas on the layout I'm working on I'll use the 1 inch foam on 1/2” plywood so I can carve a little depth into it where I want some surface relief. For the rest of the layout I'll use and foam on the layout in most places but the track work will be located on an open frame type bench-work vs. the flat plywood sheets used in the yard areas.

The following pictures will describe doing the foam/plywood/servo test....

.

For more info on the $5.00 servo controller shown above go ( HERE ).

There is a resistor that is used with the servo controller that determines how far the servo arm and the turnout points are thrown. Above I'm using the breadboard to experiment with resistor values and also the breadboard's 5 volt power supply is powering the controller. On the layout a dedicated 5 volt power supply will be used. You can find these for around $12-$15 on the internet.

I experimented with placing the piano wire at different locations on the servo arm. Depending on how your turnouts work you can fine tune things by where the wire is inserted into the servo arm or by changing the value of the resistor used in the controller or both. You shouldn't have to do this for every turnout once you come up with a good combination.

.

As a result of this test I feel good about using the servo under the plywood and 1 inch foam. It would probably work fine with even thicker foam.

=========================================

...........................On..............e..........Next Page If There Is One