.................................. Return to Sumner's Home Page....

Return to N Scale RR Main Menu.............. Return to Trackwork Menu

=========================================

..............Previous Page..............................Next Page If There Is One

=========================================

…..............................................a --- Drilling a Throwbar --- Servo for Turnout Control ---

=========================================

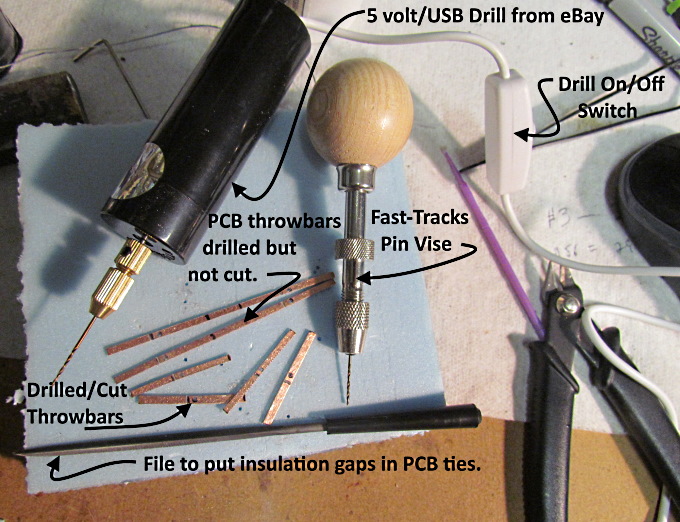

If you are building turnouts from scratch it is likely that you will have to drill a hole in the throwbar if you want to operate it with a slide switch, servo or a Tortoise Switch Machine. I had been drilling the holes in N scale throwbars with a pin vise I bought from Fast-Tracks and it worked OK, but to me was slow.

I bought a 5 volt/USB powered drill off of eBay and although the drill ran fine I wasn't very successful using it to drill the holes in the narrow throwbars. It spins very fast and the bit would wonder around so was hard to center. I finally brightened up a bit and used the pin vise to just start a hole in the throwbar. One doesn't need to drill all the way through with it, just get a hole started, then switch to the electric drill to finish the hole quickly.

(UPDATE NOTE: I've found that I don't need to drill a starter hole with the pin vise drill before using the electric drill. I take a sharp counter punch and tap a starter indention with it and a light hammer blow. Then drill the finished hole with the electric drill and a .037 bit for the throw bar throw wire I'm using, also .037.)

.

.

.

The drill is better than I expected it to be and I can see using it for other projects down the road.

=========================================

...........................On..............e..........Next Page If There Is One