................................ Return to Sumner's Home Page....

Return to N Scale RR Main Menu.................. Return to Trackwork Menu

=========================================

...............Previous Page......................................Next Page If There Is One

=========================================

…...............--- Turnout Servo Mount for One Limit Switch ---

….............--- Print files for the mount ( HERE ) ---

........... --- Need two limit switches, go ( HERE ) ---

=========================================

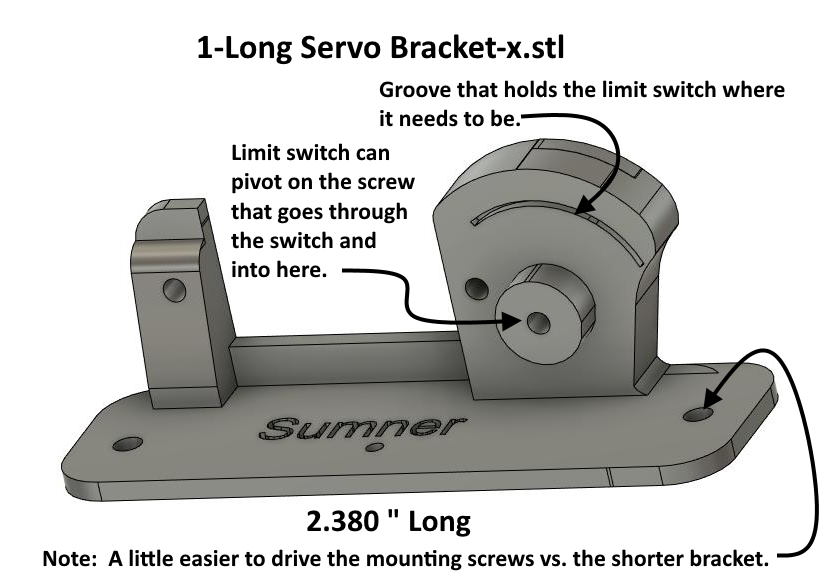

This is an update on the servo mount I've had up on thingiverse.com ( HERE ) for some time. Basically the same mount but changes in the area where the limit switch is located via a groove that the second screw on the limit switch screws into to locate the limit switches position. Also some areas have been built up a little for more strength.

The limit switch can be used to change the frog polarity, signaling or LED's or possibly something else. hem. Some of the servo mounts I've seen the limit switches are in a fixed place. If you need two limit switches you can find the servo mount for that application on the previous page or ( HERE ).

There are two versions of this bracket you can print. The one shown above is about 3/8” longer than the one two images down. It is a little easier to work a screw driver on the mounting screws with the longer one. If you need the shorter one you will still be able to work the screws that hold it to the underside of the layout.

After the bracket is printed I drill the hole for the throwbar wire to 1/16” (.063”). I drill the other mounting holes in the bracket for the servo, the limit switch and the bracket mounting holes to 3/32” (.094”). I drill the pivot hole in the limit switch to 7/64” (.109”) and the hole for the set screw to 3/32” (.094”).

I use #4 screws for all the mounting. 1/4” to mount the servo to the bracket. 1/2” for the pivot screw on the limit switch. 3/8” for the set screw on the limit switch (some times 1/2”). 3/8” to mount the bracket to the underside of the layout.

NOTE: If you are metric use the appropriate screws and pilot drill bits to work with the screws you are using. If you don't drill the holes out on the bracket you are risking breaking it when the screws are put in, especially the narrow arm on the single limit switch bracket that holds the servo on one side.

Printing the shorter bracket shown above will give you a bracket that is only 2 inches long so will fit in a slightly smaller space than the longer version further up the page. Other than the length there are no other differences.

It can be difficult at times to mount a servo in the correct place under the turnout and it needs to be pretty accurately located.

I've tried to make that a lot easier with some tools shown above that you can also print out. These will make it very easy if you are doing this as you lay track and before the turnout is in place.

Locate where you need the wire from the servo to come through the layout's surface. Will it be in the middle of the throw bar between the rails or outside the turnout and under the extended throwbar on one side of the turnout or the other? With the location of the throwbar wire hole determined drill a .025” hole there. Reach under an install the tool shown above or in the next image. If you can't reach this from the side of the layout you will need a helper or tape it to the bottom of the layout after pushing it up through the hole.

Next rotate it from the top of the layout using the pointer on the top to help locate it with the pointer pointing down the track in one direction or the other depending on which direction you want the servo mount pointed in. Next....

….. take the 'Drill Jig Grabber' shown above and slide it down the pointer rod and use a set screw to hold the 'drill jig' from falling to the ground.

Now you can go under the layout and using the drill jig drill two pilot holes for the servo mount. The should be positioned exactly where you need them. You will only be under the layout for a couple seconds drilling the two holes.

Next take the the servo mount with the servo attached, limit switches attached and a throwbar wire attached to the servo arm. Also have the two mounting screws in the mount and sticking out just a bit. Under the layout put all of that into place with the throwbar wire going up through the 1/4” hole. You should be able to move it around slightly until you feel the mounting screws drop into the pilot holes. Run the screws in and you are done.

This should take less than a minute under the layout and the wire to the throwbar should be close to perfectly centered in the 1/4” hole as shown above.

…... the video above or ( HERE ) shows how easy this is to do.

If for some reason you need to you can put the mount and servo up under the layout and grab the throwbar wire from above and put the 'Throwbar Grabber' (shown above) on it and it will hold the mount and servo from falling to the floor. This shouldn't be necessary thought if you started the screws in the mount and have them sticking out a ways.

When finished you should find the throwbar wire centered in the 1/4” hole. Slide the turnout down over it with the wire going through the throwbar hole and finish installing the turnout. When done if you are using one of the controllers shown and described ( HERE ) you can …..

adjust the servos throw as shown above or ( HERE ). It is a good idea thought to get it close as shown above with the test rig before installing it. Do that and use the mounting tools above and mounting the servo will be easy and fast with minimal time under the layout. Also you can have all of this for under $10 a turnout as described ( HERE ).

You can find the files to print this on my thingiverse.com account ( HERE ).

You can find all the files to 3D print this object and others on my thingiverse.com account ( HERE ).

=========================================

...........................On..............e.........Next Page If There Is One