.................................. Return to Sumner's Home Page....

Return to N Scale RR Main Menu........... Return to Building UP's Canyon Division Menu

=========================================

...............Previous Page.............................Next Page If There Is One

=========================================

…..............................--- Sawmill Design/Build – Pt. 2 ---

=========================================

Spending a lot of time with Fusion 360 on the sawmill and might be getting close to printing some of it….

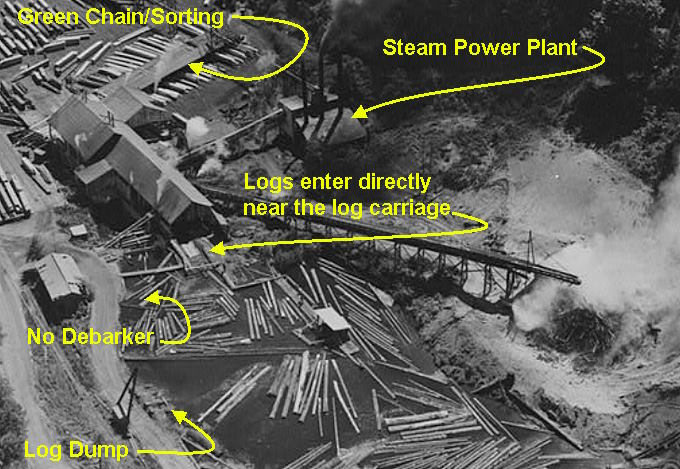

Not sure when the picture above was taken. Mill was built in the '30's. An 'A-Frame' was used for some time to unload the logging trucks (logs were never brought in by rail). Notice there was no debarker building when this picture was taken. The logs entered more directly to the log carriage to be cut similar to a lot of sawmills that are modeled.

The main building with the head band saw was narrower and the building(s) behind it along with the green chain were small but where they are now. The band saw blades then and now were sharpened in a room not far from the saw and not in an overhead loft.

A later picture is shown above and is pretty much how the mill looks today. They now dump the logs into the pond with a large forklift. There is a building with the debarker in it now. The logs are lifted by a chain lift from the pond to a track to the debarker building and on to the mill. At the mill the logs leave the track off to a side deck and a system there on to the log carriage to be cut. The main part of the mill is wider at the pond to house the new log approach to the head saw. The smaller buildings past the saw are now bigger with one large roof and the green chain has more protection, also with a larger roof.

The steam power was partially used up to 2013 making it the last (as far as I know) operating steam powered major mill. The log carriage was also recently changed to a much more modern one that doesn't require someone to ride it along with the log carriage operator.

The design I'm working on is a condensed version of what the mill looks like today and might have been close to what it was in the '60's but I don't know for sure about that. I'll have logs brought in by rail and truck. I'll move the debarker and approach to the head saw to the other side of the building and log pond. I don't have room for re-saws and other equipment they have but will have what could be a reasonable work flow.

Instead of having a separate building with finish planers I'll have the green lumber go to the yard for kiln or air drying. Then brought back to this building via a side dock/door where it can be run through a planer next to the edgers and swing saws. The planed lumber will then go to the green chain again and out to be sorted and stacked for shipment.

The mill will mostly be cutting rough sawn lumber. Large/long timbers up to 40+ feet can also be sawn somewhat similar to what Hull-Oakes still does. They will move from the head saw straight out of the mill bypassing the green chain.

About 3 days with Fusion to get to the point above. The building and roof will be broken into at least 3 parts in order to fit the build plate of the resin printer.

Still need to get windows, doors, loading/unloading docks and other items designed before starting to print. I'll have quite a few hours into this design.

To be continued............

A link to this whole build ( HERE ).

=========================================

...........................On..............e.........Next Page If There Is One