..................................

Return

to Sumner's Home Page....

Return

to N Scale RR Main Menu........ Return

to Servo Control Menu

=========================================

..............Previous

Page..............................Next

Page If There Is One

=========================================

…....---

Overview of Simple and Inexpensive Servo Control ---

=========================================

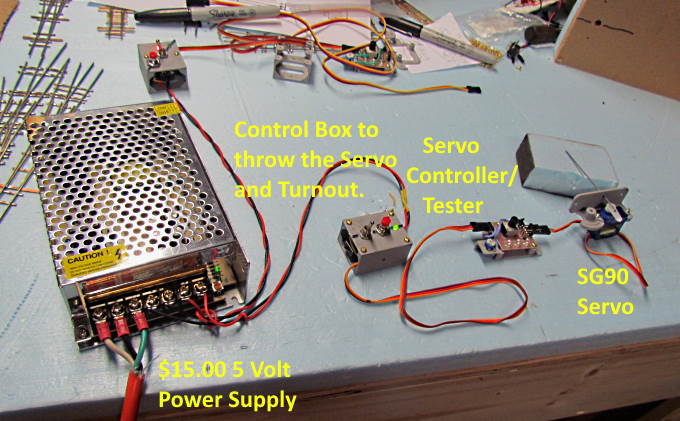

I've

been working on a way to control servos for turnouts and other uses

that is inexpensive and doesn't require using an Arduino or expensive

commercial servo controllers. If you know how to solder and have

access to a 3D printer or can find someone who does for under $8.00

you can control servos for your turnouts or other simple uses. If you

don't go the 3D printer route you can make your own servo bracket by

other means and you can still use everything else below to control

servos for turnouts or other times you need a servo controller for

simple applications.

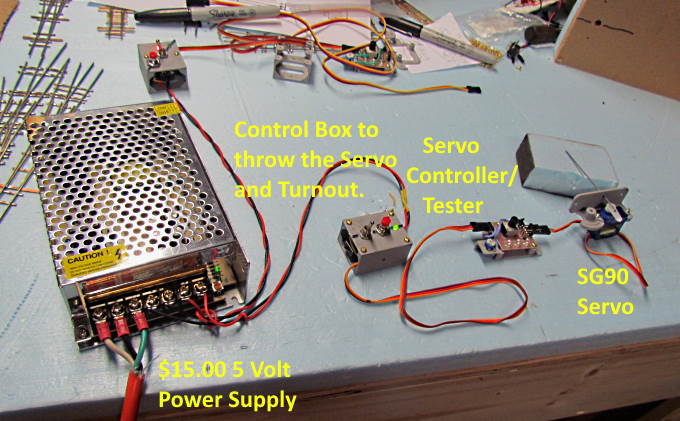

You can't control a servo with a simple

on and off switch, you need a servo controller. Dave Bodnar came up

with the idea of using a servo tester as a means of servo control. If

you buy them in quantity you can find them for as little as $1.50

each. Add about another $4.00 to that for LED's, switches, a

resistor, servo cables and a little wire and you have not just a

servo controller but also a control box that can sit at the edge of

the layout and that is used to throw the turnout and show which route

is active.

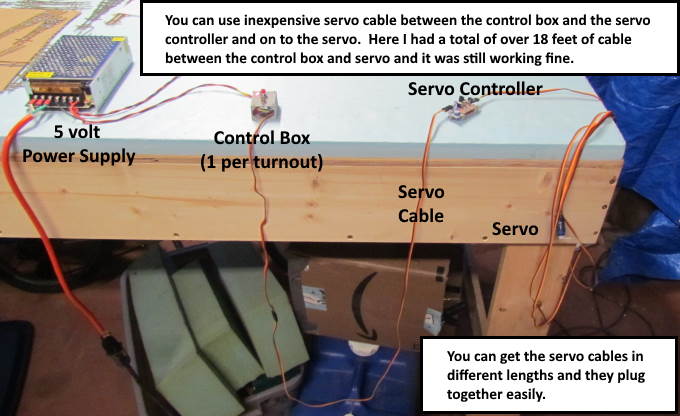

I

picked up a 5 volt power supply for $15.00 that will power about any

number of servos and controllers as they only draw current when a

turnout is thrown. You run two power wires from the power supply to

the control box. You could run a pair of wires around the layout from

the power supply and tap into them where needed.

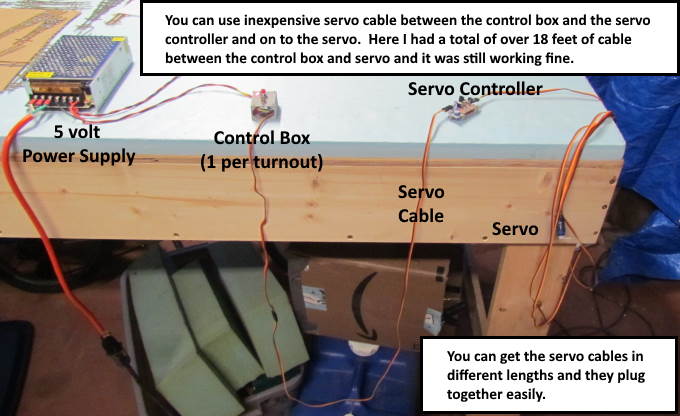

From

the control box to the servo controller and on to the servo itself

you use inexpensive 3 wire servo cables that you can buy in different

lengths and daisy chain together if needed.

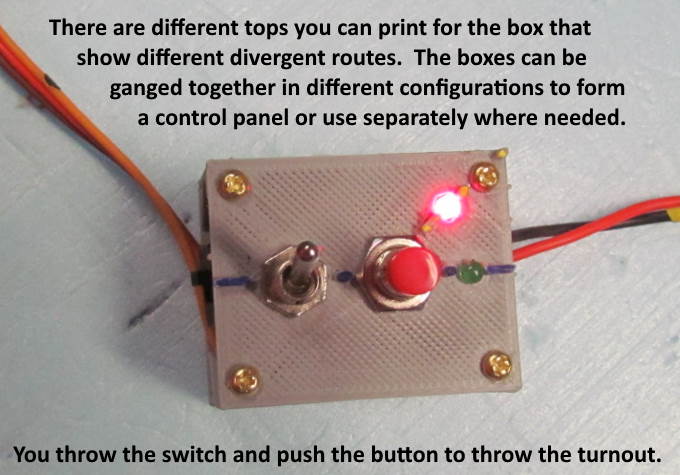

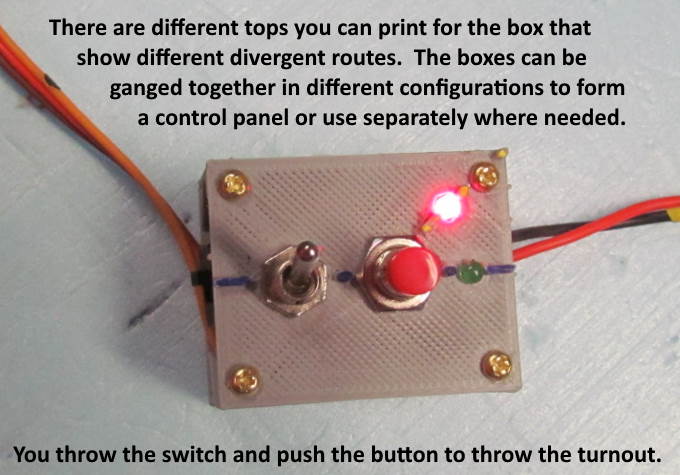

The

control box (3D printed) contains 3 switches (one not shown inside

the box), 2 LED's that show the chosen route and a resistor. On

Subsequent pages I'll post pictures of the wiring inside along with a

wiring diagram. The wiring is simple and you can wire one up in under

30 minutes once you have done a couple.

There are a number of

different tops you can print that show a left or right-hand turnout

facing different directions, curved turnouts and turnouts as you

would see them in a yard ladder. You can place the box wherever it is

needed or gang them together so as to represent the track plan. More

pictures on the following pages.

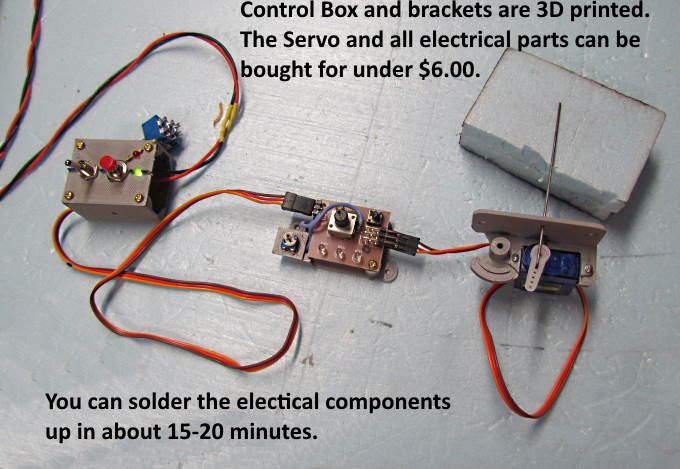

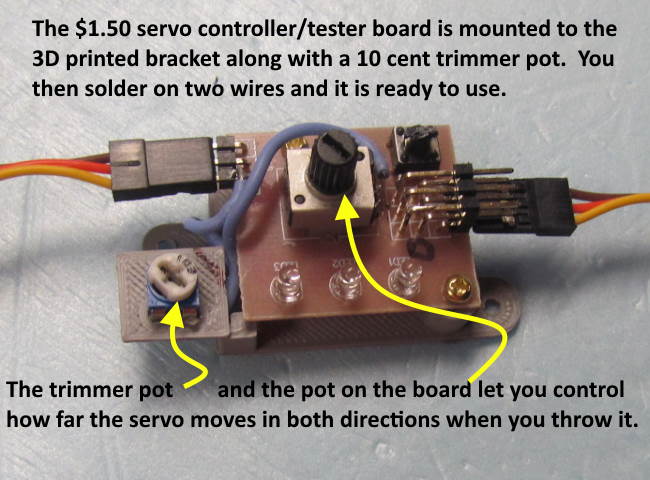

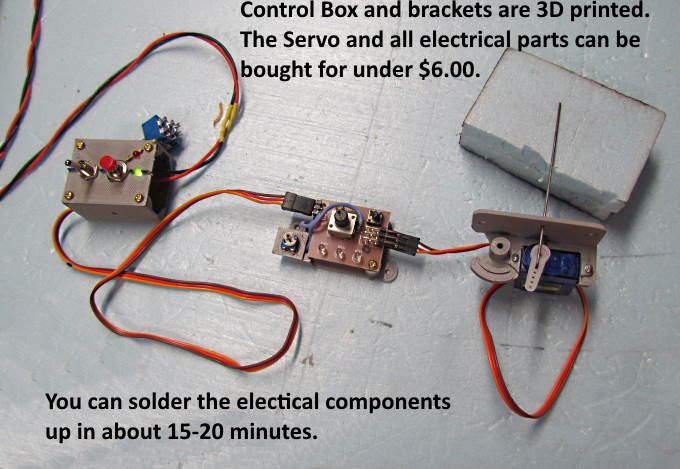

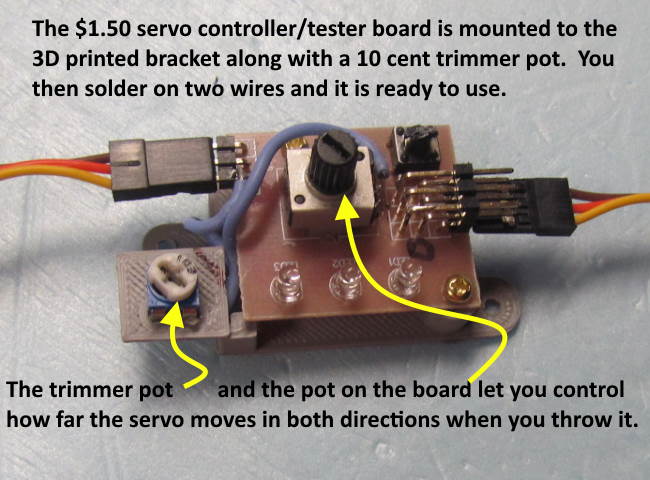

The

above board is mounted out of the way after the turnout and servo

have been installed and the throwbar travel set. You can use it to

adjust how far the servo throws the points in either direction. This

is helpful if you don't mount the servo exactly centered under the

turnout. Also the servos will throw the points way to far if you

don't have some means of controlling their throw. This way if you

need a little more or less pressure on the points it is easy to set

and can be adjusted easily in the future if needed. It will help for

the differences needed in throw depending on scale and layout

thickness under the turnout.

I took Dave's wiring example and

expanded on it a little by adding a second potentiometer (10 cent

trim pot) to the circuit. This addition is what allows you to adjust

the throw in both directions. Assembly consists of screwing the small

board above onto the 3D printed bracket and adding the trim pot to

the bracket and soldering on two wires. You could use some other

means to mount this if you don't have 3D printer access.

This

circuit is activated when you throw the toggle switch and push the

button on the control box at the edge of the layout. Another

advantage to this is that the servo is not powered all the time, only

when you throw the turnout. For this reason you don't need a large

power supply.

You

use different length servo cables between the components. Above I had

over 18 feet of cables daisy-chained together and it was still

working fine. The servo controller can go under the layout as you

only use it when you need to adjust the servo's throw on the points

so normally you would have a shorter cable than shown between the

control box and the servo controller. You can change the cable

lengths easily at any time as they plug into each other.

You

could use the components for other items on the layout where you

needed to move something with a servo and wanted to control the throw

and when it happens.

=========================================

WARNING:

One person bought Miuzei

SG90 servos on Amazon and they didn't work.

Went

90 degrees each time they were powered on. I would stay away from

them.

If

you find servos that don't work let me know.

=========================================

...........................On..............e.........Next

Page If There Is One