.................................. Return to Sumner's Home Page....

Return to N Scale RR Main Menu........ Return Roundhouse Menu

=========================================

..............Previous Page..............................Next Page If There Is One

=========================================

... --- Base and Front and Back Walls ---

On the following pages you will find info on and then the print files to build a N Scale roundhouse that can be printed and assembled with any number of stalls. This is a freelance design where I've pulled ideas from different photos but doesn't represent any real life roundhouse. I decided to give the project a set of pages all to itself since there are quite a few printed parts. They were designed using Fusion 360. I'll be adding pages to this as I print and build the roundhouse.

You will be able to find the print files on my thingiverse.com account ( HERE SOON ). I've printed all of the parts separately but have not glued all of them together at this time so you are on your own there. At this point I still have to design the roof beams. I was going to 3D print all of the flooring and roofing but as of now think I'll make those out of sheet styrene. You can 3D print the roof skylights and attach them to a flat roof. I'll also probably put up the floor section files I did make once I've modified them some so they could be used as patterns to make a floor.

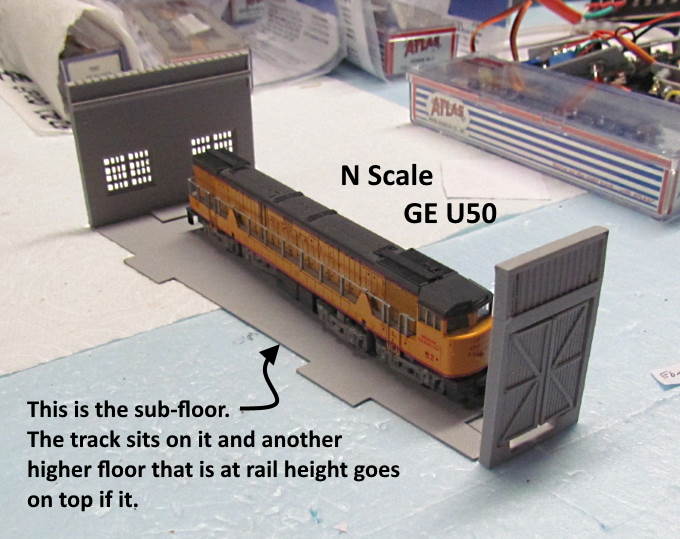

This page will be an overview that shows the initial files for one stall's floor and front and back walls. You would print and assemble as many of these as you wanted and then put side walls on to finish off the roundhouse.

====================================

NOTE: The stalls in the roundhouse are at 12 degrees to each other. Make sure that you will be able to work with that angle with the turntable you plan on using and the indexing for it. I'll be using a stepper motor and an Arduino for that myself.

The pictures here show a 3D printed floor. I will put the files up for those but I plan on using them as patterns to make a floor our of two thicknesses of styrene. I'll post when I do that.

Make sure 12 degree stalls isn't going to be a problem for you.

The back walls will be covered in more detail on a following page.

The bay front walls and doors will be covered in more detail on a following page.

.

The back walls will be covered in more detail on a following page.

.

.

.

.

Above are the 3D printed floors I designed and printed one of. I'll be using sheet styrene to accomplish the same thing. This will cut down on print times and also hopefully will work fine.

I use to see these engines along with the turbines in the late 60's when I ran a milk route near the tracks north of Laramie, Wyoming.

All of the above will be covered in more detail in the pages that follow.

=========================================

...........................On..............e.........Next Page If There Is One