..................................

Return

to Sumner's Home Page....

Return

to N Scale RR Main Menu.... Return

to 3D Printed Objects Menu

=========================================

..............Previous

Page.....................................Next

Page If There Is One

=========================================

…...

---

3D Printed Crossings by Nskale --- Servo

for Turnout Control ---

=========================================

You

can find all the files to 3D print these on my thingiverse.com

account ( HERE

).

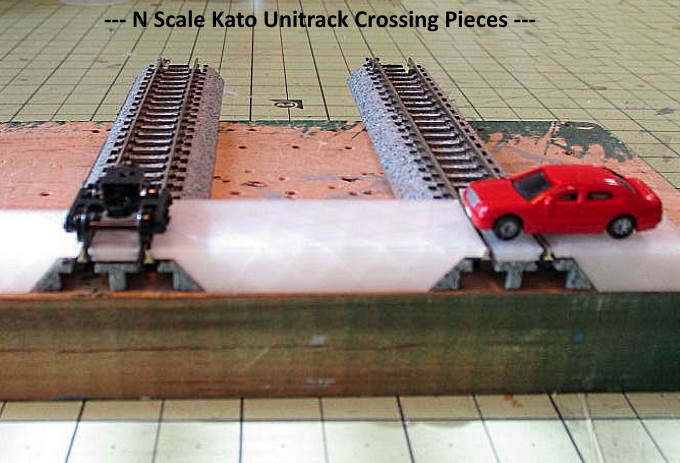

On

this page you will find some N Scale crossings by Nskale. He asked

if I would post the files on my thingiverse account and I said yes,

so you can find them there. I'll let him explain more about them....

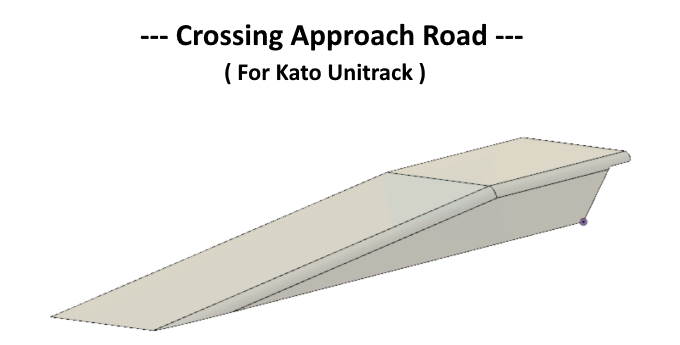

“ Well,

I went back to the intermodal scene because I got an idea for some

added detail when I did some research on RR crossing designs

(modern). I came across the modern concrete panels/inserts you can

see in the attached pic and I wanted to add some inlays like that for

the track where there might be vehicles crossing in the area. Before,

I had made them for small road crossings with pieces of balsa, but it

turns out it's a perfect task for a 3D printer.

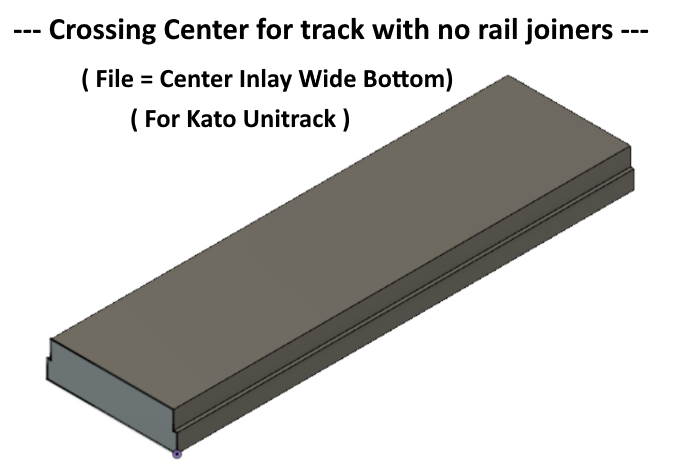

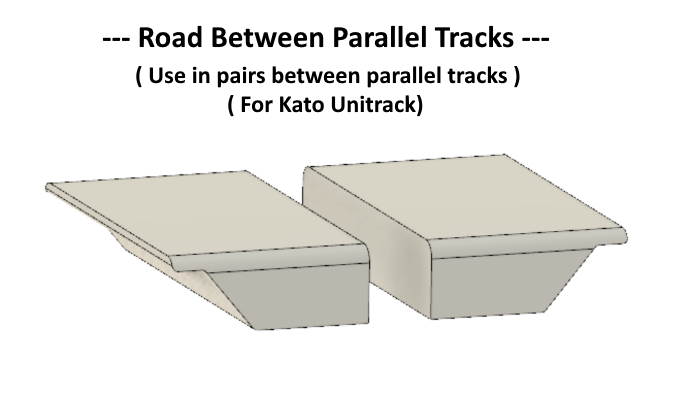

I

designed them to fit in Kato track and to be self-centering allowing

for clearance for the wheel flanges. So you see the bottom is smaller

than the top, just like the real one. The way track is manufactured,

there are small nubs at each place where there is a molded-in

crosstie (where it supports the rails). I say designed for Kato track

because I don't know the distance between the nubs for other track.

It might fit as-is or it would be a trivial matter to adjust the

width of the bottom for an exact fit. So, in order for it to fit in

all the way down, the bottom is dimensioned for the distance between

the "nubs". Above that, the top is dimensioned for the

clearance needed for proper fit for the train wheel flanges.

And,

to make it more complicated (thanks Kato), the place where the track

pieces fit together is even smaller on the bottom. This is caused by

the plastic joiners and the distance they stick out. So, there are

two possible inlays that I might need to use.

For

straight track, it's a simple matter to scale the length in the

slicing program. That means that only one part needs to be made in

the CAD program for all lengths you might need. For lengths longer

than the width of the printer bed, make more and glue in end-to-end.

“

For

much more about them and how to use them go ( HERE

).

.

.

.

.

Nskale

did a really nice job on this. Again to see more info on these and

how to use them go ( HERE

) and you can find a direct link to the files on thingiverse.com (

HERE

).

You

can find all the files to 3D print these on my thingiverse.com

account ( HERE

).

=========================================

...........................On..............e..........Next

Page If There Is One