...Return To Mine & Other Bonneville Car Construction Pages

.Previous Page...........B'ville Car Index Page...............Next Page

==================================================================

.........--- Stock GM Nodular Iron Flywheel---

........--- Spec Stage 5 Clutch/Pressure Plate---

==================================================================

The 4 cylinder (and probably 5 cylinder) Atlas manual transmission trucks (Colorado/Canyon) come with a nodular iron flywheel. It is stronger than the old cast iron flywheels, but since SCTA's rules state no cast iron flywheels unless you can show them the nodular iron has sufficient strength, you need to replace it with a billet steel or aluminum flywheel if you are going to run the car in their land speed events. With that in mind, since I'd taken the pictures and was trying to find a supplier for a steel or aluminum flywheel decided to post this info as it might help someone.

Above we see the stock flywheel held to the back of the crank with 8 10mm bolts.

The ring starter gear is a press on fit to the flywheel and that is important if you are having a flywheel made as they can probably use this ring gear which simplifies making a new flywheel to some degree.

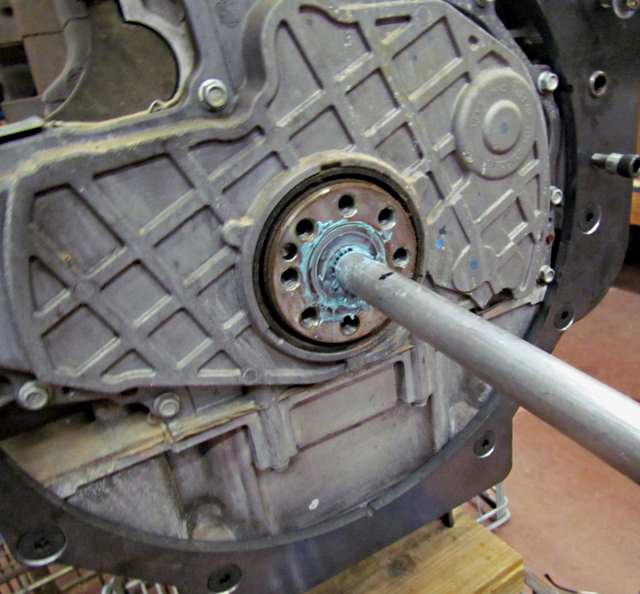

To remove the flywheel I spent a few minutes making the tool shown above just below the speed-handle. Not much to it.

The tool is held on the flywheel with 2 of the pressure plate bolts and stops the flywheel from rotating which makes removing the bolts very easy. I won't be using the bolts over as they are some of the GM where you torque to an angle and are only suppose to be used once. I'll switch to ARP bolts for the flywheel and the clutch pressure plate.

The clutch pressure plate side and .....

.... the engine side. Note the center .....

... has a snout on it that indexes into the end of the crank where as a number of cranks have a flange on them that the clutch locates on.

Here I'm pressing the old pilot bearing out by packing the inside cavity behind the bearing with grease and taking a bar I'd turned down to the diameter of the transmission input shaft and driving it into the grease which then presses the bearing out. It takes multiple times of filling the cavity behind the bearing as it moves out to accomplish this, but it works well.

The bearing matches size wise with the pilot bearings found in the newer LS motors and McLeod has a pilot bearing that is thicker (P/N 8617) and is what I'll use since the adapter plate being used moves the transmission back from the motor.

The snout on the flywheel and the pilot bearing both have the same I.D. as far as I could tell with my mics.

Above you can see the ring gear has 161 teeth, not a very common number. When I thought I could run this flywheel I ordered the Spec Stage 5 clutch assembly above. It is not recommended...

.... for the street...

... due to the disc that comes with it. The clutch is smaller in diameter than what most GM's have had with the disk being just a little over 9 inches.

With the G-Force transmission the clutch won't be used much if at all since it can be pulled into gear going off the push truck and shifted without the clutch and then popped into neutral at the end of the run.

If I can find someone to make the new flywheel I'd like it drilled for the a Spec Clutch and also for a larger easier to find GM type clutch.

I'll have more info here when I come up with a source for the new flywheel,

Sumner

==================================================================

Next Page... Next Page