...Return To Mine & Other Bonneville Car Construction Pages

.Previous Page...........B'ville Car Index Page...............Next Page

==================================================================

.........--- G-Force 101A Transmission Information---

........................................--- Page II---

==================================================================

Let's take a closer look at the .....

...the 101A shown above on the back of my GM Atlas 2.9 liter engine. I ordered it with the V-Gate shifter which once in 1st is a single plane back and forth 4 speed shifter. The squeeze handle on the shifter is used once to get the transmission into 1st. Pull it and move the shifter forward and you are in first. Then back into 2nd, forward into 3rd and back again into 4th. The rear short handle is to move the transmission into reverse.

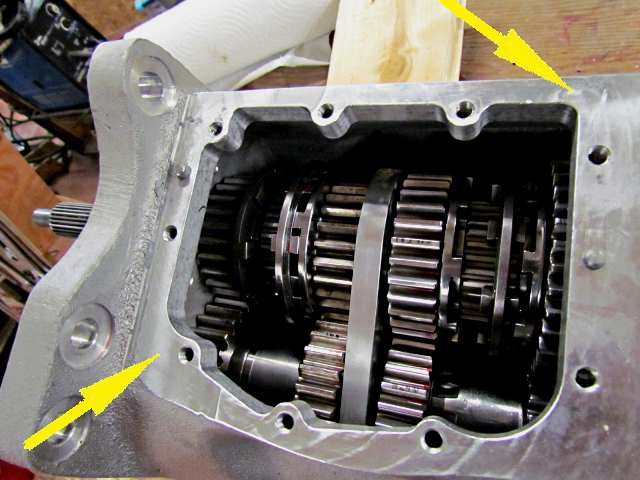

Above some of the linkage has been disconnected and the transmission inspection cover has been removed.

The earlier 101's had an O-ring in a groove around the mating surface for the cover. At the time I bought this one they no longer machined the groove in for the O-ring and now use a sealant on this surface only, no gasket. They told me that over time the O-ring would become crushed and start to leak. Hooley's has the O-ring and no leaking so far.

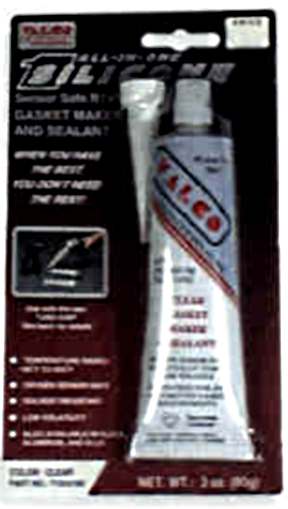

G-Force recommends using....

...Valco Cincinnati's All-In-One Silicone to seal the inspection cover and is what they use. I bought the aluminum in the 3 oz. tubes (P/ N 71195). I also...

...bought their Tube-Grip dispenser and love it. I've always hated squeezing tubes and it works great. I also bought extra replacement nozzles as they were not expensive.

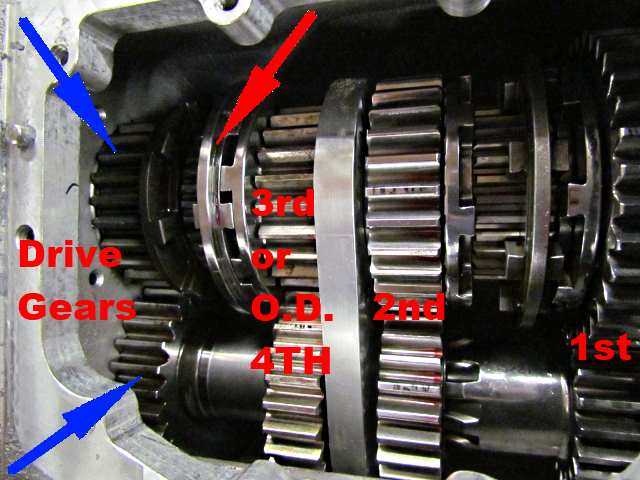

The blue arrow points to the full cuff that makes the 101A stronger than the previous versions. Under load the two shafts want to separate from each other. The cuff between they through which they both go resists the spreading and makes the transmission stronger. The first Tex 101's had no cuff. Then I hear there was a half cuff, but haven't seen that and I don't know which shaft it supported. The the "A" went to a full cuff as shown.

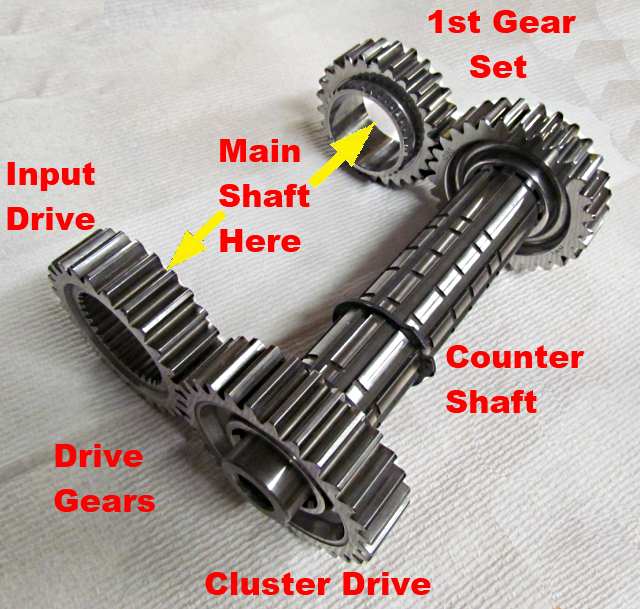

The top middle arrow points again to the 'cuff'. The other two arrows point to the 1st gear set. Notice how the bottom gear is integral to the countershaft (all one piece). There are a number of gear ratios available with the integral 1st gear but the highest is 1.932 using a 26/30 input/cluster drive set. If you get the splined countershaft where 1st gear is not integral and slides on then you can go to taller gears for 1st. That can be important for a land speed car where a lower first just means spinning the tires. A taller first can help with traction and allow a shorter drop going into 2nd. We started with a 1.949 1st with Hooley's Stude and still spun the tires at anything over 50% throttle in 1st.

To the left above are the drive gears. The top one is splined to the transmission input shaft and spins all of the time. It drives the bottom gear, bottom left arrow, which is splined to the counter shaft and thus spins it at all times. You can change the drive gear sets between different ratios which allows you to change one set of gears and this results in 1st, 2nd and 4th becoming either higher or lower ratios.

The top red arrow points to one of the two sliders that determines the gear selected as they move via the shift forks. The one over to the right on the main shaft selects either 1st or 2nd by dogging into one or the other of those gears and connecting the chosen gear set to the main output shaft.

If the slider where the red arrow is moves to the left it dogs the input drive gear which is connected to the input shaft to the output main shaft and gives you your 1:1 4th gear. If it dogs to the right it connects the 3rd gear set to the main output shaft. Normally this would be your 1:1 4th gear but if you use overdrive gears in this location then the 3rd gear set actually becomes an over drive 4th and now third is 1:1. The transmission can still shift normally with the V-gate or with an "H" shifter if you turn the shift arm on the outside that is connected to the linkage over.

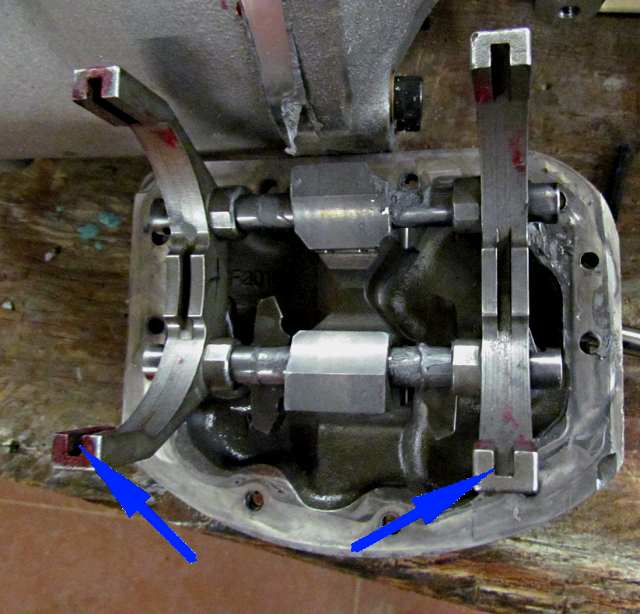

Now for one of the reasons you need to be careful in getting parts for the older 101's vs the 101A is the introduction of the 'full cuff'. To make room for the full cuff some of the components had to become narrower. This was accomplished with the sliders. You can see above that the sliders have a male component to them that the female shifter fork, next picture, connects to . As I understand it the earlier 101's without the cuff had this reversed. The slider was female and the shifter fork was male. That made the sliders wider. By changing them to male they could be made narrower. This freed up room on the shaft for the full cuff. From this I'm assuming that the half cuff was probably just on the lower countershaft, but that is a guess. Once again if you are buying do it right the first time and get the 101 with the full cuff like above.

The blue arrows point to the female part of the shifter forks.

I wanted the option of a taller 1st than what was possible with an integral 1st gear on the countershaft so also received the above countershaft with my transmission. I'll start with the integral 2.067 1st on the countershaft and if I need to go taller I'll switch to the countershaft above. Don't forget though that the drive gears also account for the overall gearing in each gear. My transmission came with 25/31 drive gears and 35/21 1st gear set. If I change my drive gears to 26/30 and keep the same 1st gear set it will now be 1.923 vs. 2.067.

Above you can see how the drive gears drive the countershaft and I used one of my other gear sets to show how a 1st gear set would look where the countershaft 1st gear slides onto the shaft.

When buying drive gear sets they should look like the ones above. Small splines on the input drive gear that resides on the transmission's input shaft and the cluster drive gear that has larger splines to mate to the countershaft.

Gear sets for the 101A should look like above. The left gear rides on the countershaft. The main shaft gear to the right freewheels with its smooth bore on the main output shaft. It connects to the shaft via another pieced that rides on the side splines and that is splined to the main shaft. The sliders dog in and out of the other pieced, see pictures further above.

If you are ordering gear sets on the Internet make sure they look like the ones above and are meant to work with the 101 you have.

Andrews also made gear sets that fit these transmissions and you will find them on ebay and other places. The ones I've seen are narrower at the teeth but the same thickness at the hub as can be seen by the one set we have above. The teeth have an entirely different shape to them so you have to use them as a set. I've been told, not sure if it is true or not, that despite the teeth being narrower they are as strong or stronger than the Tex and G-Force gears. They have their own tooth counts that don't match the G-Force gear selection chart. Just divide the teeth for the ratio and go from there.

Be aware that some gears might not physically fit inside the case. I have not tried putting the Andrews set shown above in the transmission case but worry that the diameter of the countershaft gear might be too large to fit. With the present cases on the 101A I was told by G-Force that their 32 tooth countershaft gear is the largest that will go into the case without possibly clearancing the case. That is the 32/23s gear set on their chart which is an overdrive gear set.

I've marked the ratios of the gears inside of my transmission on the top and Hooley has done the same. As you can see I have a .891 overdrive 4th in the transmission as it was ordered. I do have other drive gears and will change out the overdrive 4th gears to lower gears that will be 3rd and the 1 to 1 gear will become 4th. I'm hoping the lower gears will help to qualify the car for the long course as max rpm in 3rd should be about 180 mph. There is lots you can do with this transmission.

The right arrow points to the drain plug and the left arrow points to the fill-to plug hole. It is fairly quick to change the drive gears or the gear sets in the transmission. Out of the car gear changes can be done in less than an hour once you have done it a time or two (probably under 30 minutes for someone good). The transmission is robust but not real complicated.

The right arrow points to the reverses lever and the left to the pull that is needed to get up into the 1st-2nd gate on the shifter.

I'm hoping that this shifter will work well with the rear mounted engine in the lakester. I won't need to provide an "H" pattern to my linkage, just fore-aft.

The bottom arrow points to a pin that locks the whole shift mechanism and needs to be pulled out for the shifter to work. You could just leave it out. The shifter has an upper gate/track for 1st/2nd and the lower is for 3rd/4th. You can see how when you pull the lever on the handle it moves the shifter into the upper gate/track. Once up there and with the lever forward you are in 1st. The lever can now be released and pulling back on the shift handle will find you in 2nd. Push forward and it drops down into the lower gate/track and you are in 3rd. Back again and you are in 4th. It is a very sound sure feeling shifter.

Their "H" pattern shifter that we have used on the Studebaker is also a very good shifter but we have missed shifts with it a couple times. Not really the shifters fault but how the driver sits in the cage makes for somewhat awkward shifting with how your arm can move and also the fact that you drive the car so little. I think if the car had the V-gate in it there would of been no miss shifts.

With this type transmission and the way the dogs engage the gears you want shifts to be fast and sure to protect those dogs. Most of the time Hooley has shifted without the clutch. Just dip the throttle and bang the next gear. It would would also work well if there was ignition cutout for less than a second during the shift. If you use the clutch you want to be fast with it also, don't slow shift the transmission. Two years we had throwout bearing problems and would push the car off in neutral. Once up to 40-50 Hooley would push it into 1st and pull away. Then do the shifts without the clutch doing a quick off/on with the throttle and popping it into neutral after the chute was out. The V-gate could also work exactly the same.

If you are looking for a lot of gearing options and the ability to handle high HP I can't think of another transmission that is in the same cost range with the availability of good slightly used gears to chose from at affordable prices. This transmission has the ability to change meeting your gearing needs as you change engines sizes or HP levels over the years.

==================================================================

Next Page... Next Page