........................Endeavour Index Page............Plumbing Mods Index Page

..................................Previous

Page..............................

Next

Page If There Is One

======================================================

............................................--- 3 Bilge Pumps -- Part II --

======================================================

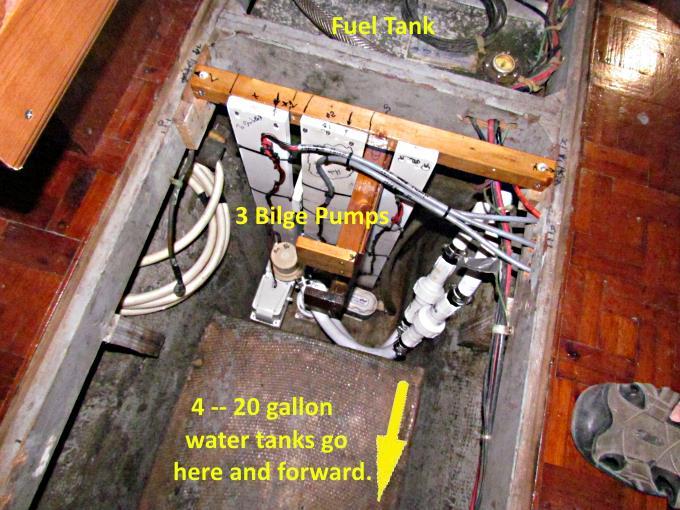

It is now the spring of 2017 and I finally get back to the bilge pumps as we think we might be getting close to getting the boat into the water again. With a resumption of work on the pumps not much will remain from the previous page.

There are still 3 pumps as shown above. The lowest and smallest is basically a maintenance pump to deal with nuisance rain water that gets into the bilge when the boat is in the yard. It is a Rule 500 that has an internal float on/off switch and is connected to a thru-hull that is no longer used. the discharge from it passes through a vented loop before the thru-hull.

Above it are two Rule 2000 pumps. Each of them has a float switch and they are stepped with one being above the other.

All of the discharge lines have been replace from the pumps to the thru-hulls. The flexible lines are 1 1/8 inch discharge lines designed for bilge pumps. The line from the smaller bottom pump goes to a nearby thru-hull via a vented loop as mentioned. The lines from the high capacity pumps go to the stern where they exit with vented loops and out of the boat via thru-hulls that are above the waterline.

On the two high capacity pumps the flex lines off the pumps go to two quick disconnect fittings that are straight through and don't restrict the water. These are not check valves as you don't want them in your discharge lines. If a pump needs to be serviced or changed out they make that easy. Uncouple the fitting and take the screws out of the pvc board holding the pump and lift the board and the pump out.

The pumps were all wired with new wiring designed to be used with bilge pumps and in their environment. The wiring goes to new electrical panels where .....

...... each pump is on a different switch.

Center is 'Off' on the switches. Up is manual 'On'. Down is 'Auto', where the pump is controlled by its individual float switch in the bilge. LED's above each switch indicate if the pump is in the 'Auto' mode or has been 'Manually Turned On' or is currently 'Off'.

To continue with the plumbing, the flexible lines continue up a few feet into the engine compartment where ...

... they transition to 1 inch pvc lines that are supported by clamps here and ....

... by more clamps ....

... on their journey in a straight shot to the rear lazarette. The original line from the bilge to the stern snaked all over everywhere and as was mentioned on the previous page didn't work when we bought the boat.

The straight PVC pipe enters the lazarette at the lower right above and then makes it to a flexible hose attached to the thru-hull in the upper left above. More high flow quick disconnect fittings are used here to make any maintenance down the road easier.

Here we see both lines finished.

Supports where made to support and protect .....

... the lines in the lazarette. Also only soft items will be stored here.

The lines are held to the supports with clamps. The lines raise up at the transom before going back down to the thru-hulls so are in actuality vented loops by use of the 'T' fittings that have been installed before they drop back down.

Two standoff fittings were made to screw into the 'T' PVC fittings. The ends are plugged but a small vent hole was drilled in the plugs.

Above you can see them installed.

With the pumps in place and wired and plumbed it was a time to test the system out. The bilge was filled with water above the top pump and then the pumps were put on 'Auto'. It only took a few seconds and the water was down below the top pump and it shut off as all three pumps where pumping at this point. In a very short time the water was below the second pump and it shut off. The maintenance bottom pump then quickly removed the remaining water.

Water was coming out the back of the boat with such force that it dug a hole in the ground below the boat. I spent a couple years worrying about getting bilge pumps working properly on the boat and we couldn't be happier with the results. All of the plumbing is now easy to inspect and we will keep an eye on it as we use the boat but having pumps that actually move a lot of water quickly will give us peace of mind.

=======================================================

............................................................................. Next Page If There Is One